In the wave of rapid urbanization, building noise has emerged as an "invisible killer" threatening human health. Long-term exposure to noise levels above 60 decibels (dB), common near major roads and airports, can lead to hypertension, insomnia, and even cognitive impairment. Particularly challenging is low-to-mid-frequency noise (such as subway vibrations and vehicle engine sounds), characterized by strong penetration and difficulty in mitigation, which has become a central concern for urban residents. Addressing this challenge, vacuum insulated glass (VIG), with its innovative technology, presents a novel solution to meet acoustic insulation standards, turning the concept of "quiet residences" into reality.

I.Challenges in Noise Mitigation and the Solution Offered by Vacuum Insulated Glass

Low-to-mid-frequency noise (100-500 Hz) is notoriously difficult to manage due to its long wavelength and high energy, rendering conventional insulation methods inadequate:

Single-pane glass: Provides only 20-25 dB noise reduction, insufficient against traffic noise.

Insulated glass units (IGUs): Air layers easily resonate with low frequencies, sharply reducing their noise reduction capability to below 25 dB.

Laminated glass: Can absorb some vibrations but lacks sufficient thermal insulation, resulting in poor overall energy efficiency.

Vacuum insulated glass directly addresses these challenges. Its core design consists of two layers of tempered glass separated by a vacuum space evacuated to less than 0.1 Pa, effectively disrupting the path of sound transmission through a mere 0.3 mm vacuum gap. Taking LandVac titanium vacuum insulated glass as an example, the weighted sound reduction index (Rw) achieves 39 dB, offering a noise reduction of 33 dB at 250 Hz, outperforming standard IGUs by 32%. This makes VIG a leading solution for combating low-to-mid-frequency noise pollution.

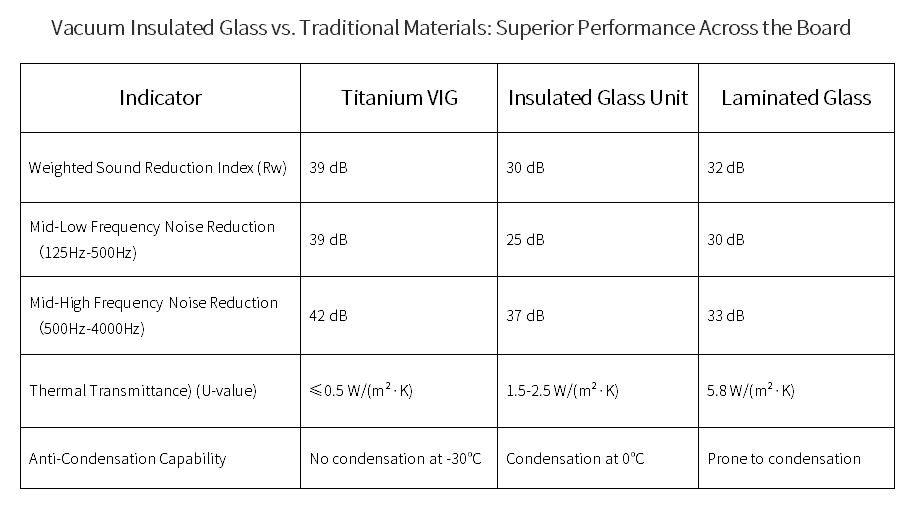

II. Vacuum Insulated Glass vs. Traditional Materials: Superior Performance Across the Board

Core Advantages:

1. Dual Breakthrough in Acoustic and Thermal Insulation

Vacuum insulated glass (VIG) simultaneously blocks sound waves and heat conduction through its vacuum layer, achieving an exceptionally low thermal transmittance (U-value) of 0.4 W/(m²·K)—three to five times better than traditional insulated glass units (IGUs). Empirical measurements from an apartment facing a busy street in Beijing showed a winter indoor temperature increase of 3-5°C after installing VIG, alongside a 40% reduction in air conditioning energy consumption. Additionally, indoor noise levels dropped significantly from 72 dB to 35 dB, demonstrating a combined benefit of noise reduction and energy saving.

2. Effective Mitigation of Low-to-Mid-Frequency Noise

The vacuum gap eliminates air-borne sound transmission, leaving only solid-borne sound transmission through the glass itself and its supporting elements. By optimizing support spacing (at 55 mm intervals) and employing titanium sealing technology, acoustic bridging effects are reduced by 60%. As a result, low-to-mid-frequency sound insulation effectiveness has improved dramatically, reaching over 33 dB.

3. Long-Term Stability and Safety

Utilizing a flexible titanium sealing process ensures a product lifespan of over 25 years, effectively addressing the common failure issue associated with conventional vacuum glass.

III. Application Scenarios and User Benefits

1. High Noise-Sensitive Areas

· Residences near airports and transportation hubs: Vacuum insulated glass effectively reduces mid-to-low-frequency noise (around 75 dB) from major roads, elevated highways, and railways to below 36 dB, meeting nighttime noise standards (≤40 dB) stipulated in the Environmental Quality Standard for Noise.

· Hospitals and schools: When combined with composite structures (e.g., VIG plus laminated glass), acoustic insulation performance can reach 45 dB, creating quiet, distraction-free environments for medical rooms and classrooms.

2. Essential Energy-Efficient Retrofit Projects

Driven by "dual-carbon" goals, vacuum insulated glass has become the optimal choice for energy-efficient renovations in existing buildings. For instance, during the renovation of an older residential community in Shanghai, replacing existing windows with vacuum insulated glass reduced overall building energy consumption by 15% and cut noise complaints by 90%.

3. Premium Residential Upgrades

In a villa project located in Shandong Province, vacuum insulated glass was employed to maintain clear views while consistently keeping indoor noise below 30 dB, significantly enhancing the quality of high-end living environments.

IV. Future Trends: From Technology Leadership to Widespread Application

Although vacuum insulated glass currently carries a higher cost, prices are steadily declining by approximately 10% annually due to mass production and continuous technological advancements. Users can prioritize critical areas such as bedroom windows for initial upgrades to manage costs effectively.

Simultaneously, supportive policies are accelerating application:

· China's General Specification for Building Energy Efficiency and Renewable Energy Utilization has included vacuum insulated glass in its priority promotion list.

· The EU's Horizon 2030 program plans to invest €200 million in developing low-cost vacuum insulated glass production lines.

V. Conclusion

Vacuum insulated glass represents not merely a technological breakthrough, but a new definition of healthy living. When low-to-mid-frequency noise is effectively mitigated, and condensation and high energy consumption become problems of the past, quiet living will no longer be a luxury in urban environments. With industrial maturity and favorable policies paving the way, vacuum insulated glass is moving beyond niche applications into mainstream homes, enabling urban residents to finally experience life with the "mute button" turned on.